As a business owner or supply chain manager, you understand the importance of quality control in manufacturing. However, when it comes to Chinese manufacturing, quality control can be a complex and challenging process. In this article, I will guide you through the complexities of quality control in Chinese manufacturing and provide actionable tips to ensure that your products meet the highest standards.

Understanding Quality Control in Chinese Manufacturing

Quality control refers to the process of ensuring that products meet the desired quality standards. In Chinese manufacturing, quality control is a critical component of the production process. However, there are many challenges that businesses may face when implementing quality control measures in China.

One of the primary challenges is the cultural differences between Chinese and Western business practices. For example, in China, there is a culture of “saving face,” which means that people may not always be honest about quality issues to avoid embarrassment. Additionally, there may be a language barrier between the Chinese manufacturer and the Western buyer, which can make communication difficult.

Another challenge is the lack of transparency in the Chinese manufacturing industry. It can be challenging to verify the quality of the materials used in production or the manufacturing processes used. Furthermore, there may be discrepancies between the samples provided by the manufacturer and the final product.

Common Quality Control Issues in China

There are several common quality control issues that businesses may encounter when working with Chinese manufacturers. These issues can range from minor defects to more significant quality concerns that can result in product recalls or even legal action.

One of the most common issues is poor workmanship. This can include uneven stitching, loose threads, or crooked seams. Poor workmanship can be challenging to detect, especially if the product is complex or has many components.

Another common issue is the use of substandard materials. Chinese manufacturers may use lower-quality materials to cut costs, which can result in products that do not meet the desired quality standards. For example, a manufacturer may use a cheaper, less durable plastic in a product that should be made from a higher-quality material.

Finally, there may be issues with product specifications. This can include incorrect sizing or measurements, incorrect labeling or packaging, or deviations from the agreed-upon product design.

Importance of Quality Control in Chinese Manufacturing

Despite the challenges, quality control is essential in Chinese manufacturing. Ensuring that your products meet the desired quality standards can help to protect your brand reputation, reduce the risk of product recalls or legal action, and increase customer satisfaction.

Furthermore, implementing robust quality control measures can help to identify issues early in the production process, which can reduce the cost and time associated with resolving quality issues later on.

Quality Control Inspection Services in China

One way to address the challenges associated with quality control in Chinese manufacturing is to work with a quality control inspection service. These services can provide a range of inspection and testing services to ensure that your products meet the desired quality standards.

There are several types of quality control inspection services available in China, including pre-production inspections, during production inspections, and pre-shipment inspections.

Pre-production inspections are conducted before production begins and can help to identify potential quality issues early in the process. During production inspections are conducted during the production process and can help to ensure that the products are being manufactured according to the agreed-upon specifications. Pre-shipment inspections are conducted before the products are shipped and can help to ensure that the final products meet the desired quality standards.

How to Choose a Quality Inspection Company in China

When choosing a quality inspection company in China, there are several factors to consider. First, you should ensure that the company has experience working in your industry and with the type of product you are manufacturing.

You should also consider the company’s reputation and track record. Look for reviews and testimonials from other businesses that have used their services to ensure that they have a good reputation for providing high-quality services.

Finally, you should consider the cost of the inspection services. While cost should not be the only factor you consider, it is essential to ensure that the services are within your budget.

Best Practices for Quality Control in Chinese Manufacturing

In addition to working with a quality control inspection service, there are several best practices that businesses can implement to ensure that their products meet the desired quality standards.

First, it is essential to establish clear quality requirements and specifications with the Chinese manufacturer. This can include providing detailed product designs, materials specifications, and quality standards.

Second, it is important to conduct regular quality inspections throughout the production process. This can help to identify issues early on and ensure that the products meet the desired quality standards.

Finally, it is essential to maintain open communication with the Chinese manufacturer throughout the production process. This can help to ensure that any quality issues are addressed promptly and effectively.

Addressing Quality Issues with Goods Produced in China

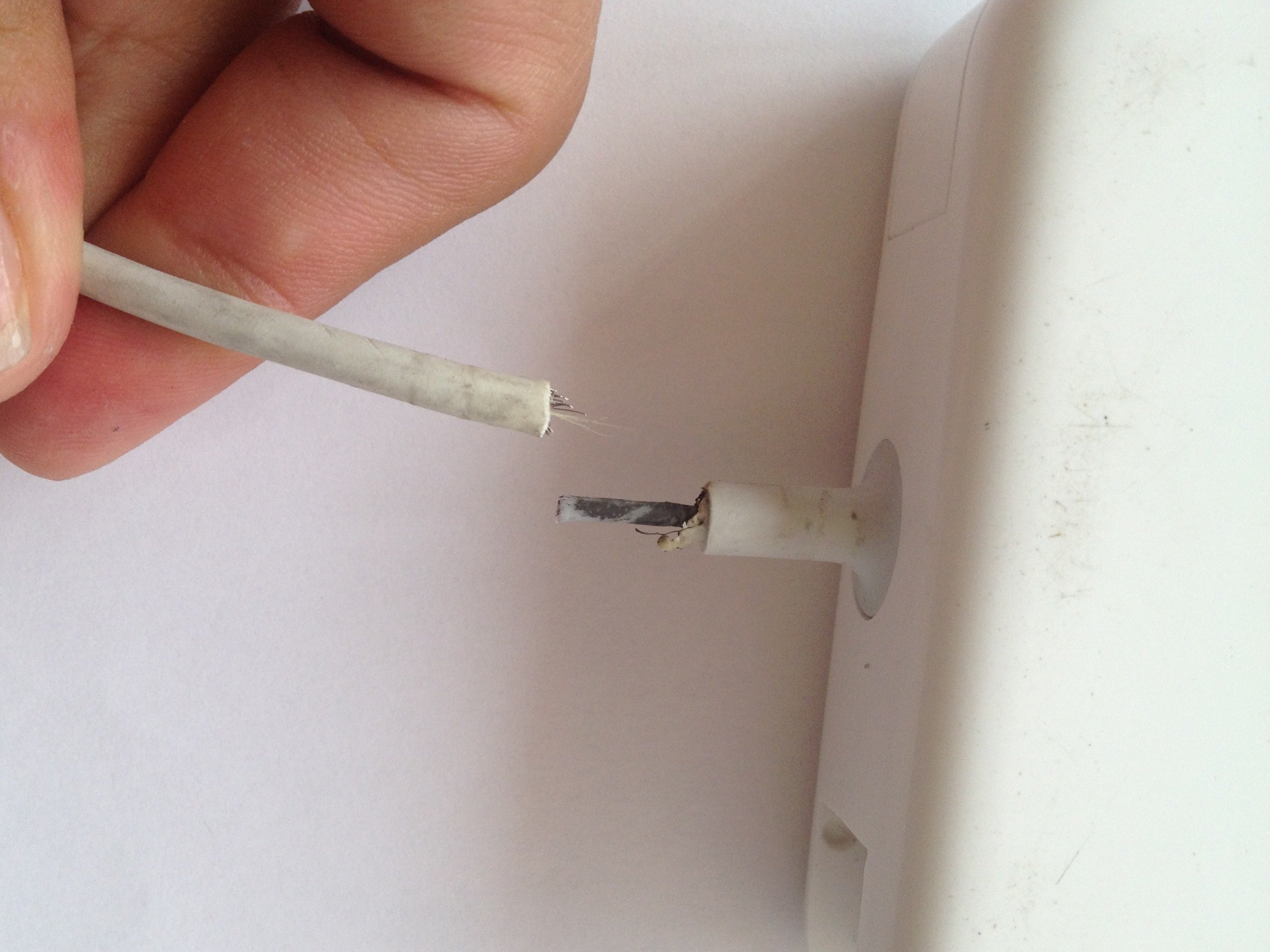

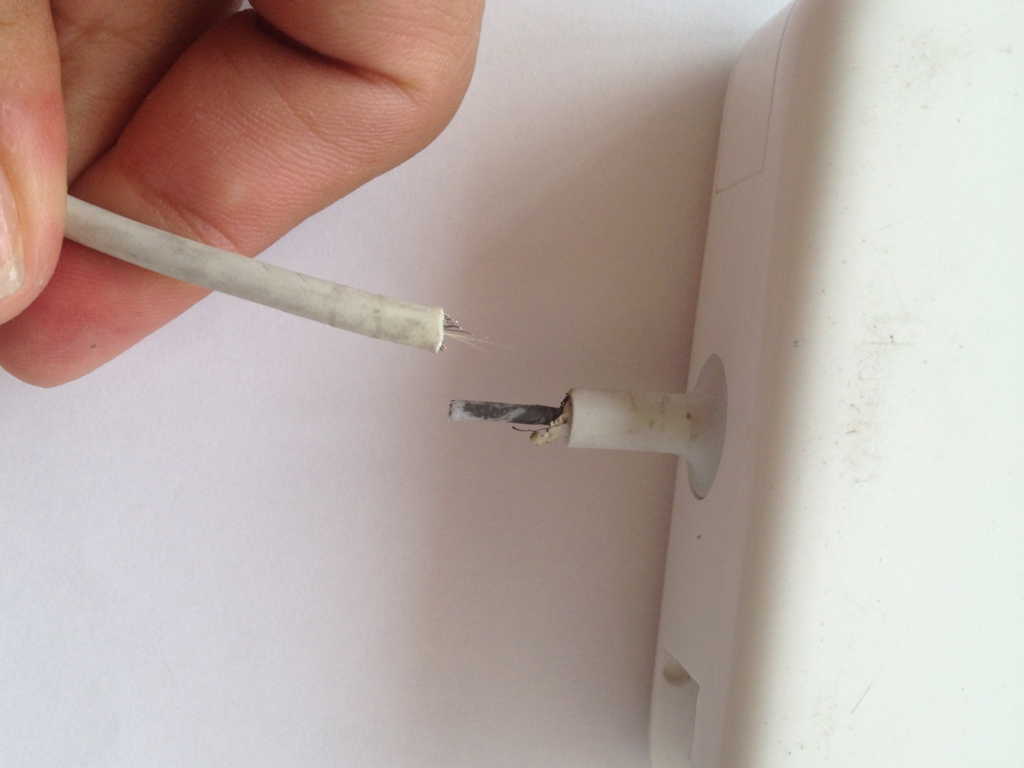

If you encounter quality issues with goods produced in China, there are several steps you can take to address the issue. First, it is essential to document the quality issue thoroughly, including photographs and a detailed description of the issue.

Next, you should contact the Chinese manufacturer to discuss the issue and work together to find a solution. If the issue cannot be resolved through communication with the manufacturer, you may need to consider legal action or product recalls.

Outsourcing Quality Control in China Manufacturing

Outsourcing quality control in China manufacturing can be a cost-effective way to ensure that your products meet the desired quality standards. By working with a third-party quality control inspection service, you can access a range of inspection and testing services without the need to establish an in-house quality control team.

Outsourcing quality control can also help to reduce the risk of cultural or language barriers that can make quality control challenging in Chinese manufacturing.

Quality Control Standards in China

China has established several quality control standards to ensure that products manufactured in the country meet the desired quality standards. These standards include the China Compulsory Certification (CCC) and the China National Accreditation Service for Conformity Assessment (CNAS).

It is important to ensure that your products meet the relevant quality control standards before importing them into your home country. Failure to do so can result in legal action or product recalls.

Conclusion

Quality control in Chinese manufacturing can be a complex and challenging process, but it is essential to ensure that your products meet the desired quality standards. By understanding the common quality control issues, working with a quality control inspection service, and implementing best practices, businesses can navigate the complexities of quality control in Chinese manufacturing and ensure that their products meet the highest standards.

If you need help managing your production in China, contact us to learn more about our services.