China's Rising Electroplating Prices

What is Electroplating?

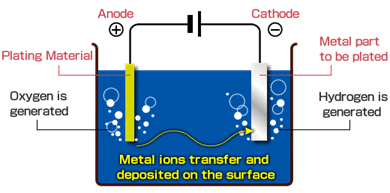

Electroplating is the process of using electrolysis to attach a metal film to the surface of metal. Usually taking one type of metal and coating it with another type. Gold plated jewellery is an example. Tin cans are not just tin, they are steel cans with a layer of tin. The steel offers the low cost and strength and the tin is corrosive resistant.

The Process

Electroplating is done by putting the metal you want to use to coat and the metal you want to be coated into a chemical solution (usually an ionic solution containing metal atoms that we want to coat with) then running a positive charge through the metal you want to do the coating to the metal you want to get coated.

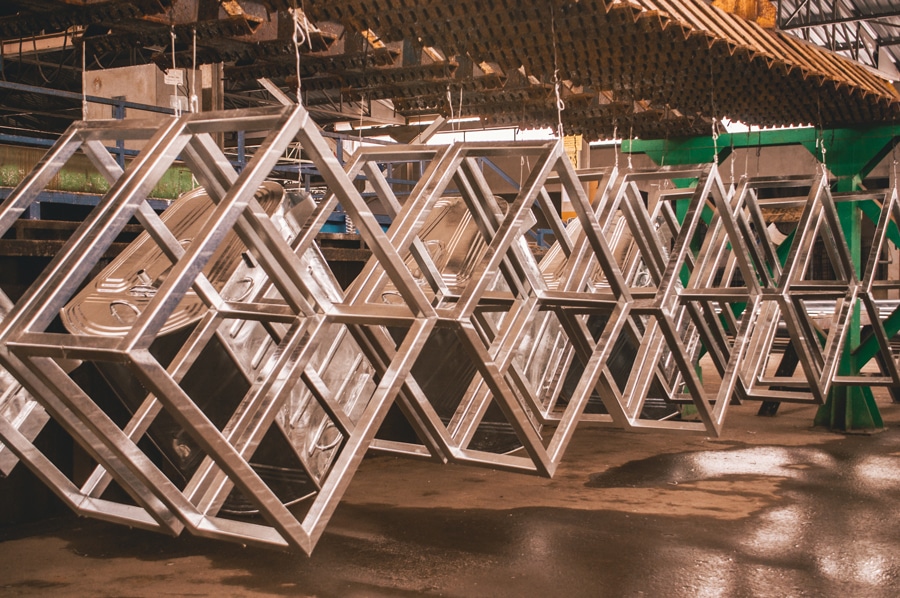

What it is Used For

To prevent metal oxidation (Such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance (copper sulphate, etc.) and enhance aesthetics.

As previously mentioned electroplating is often used for low cost aesthetics. Coating a cheap metal in a more expensive metal gives the same finished appearance at a fraction of the price.

Techniques such as galvanisation makes metal self healing. If the outer layer of zinc is damaged its surface naturally covers the exposed metal.

What’s the Problem

Electroplating is a dirty business involving lots of chemicals ending with toxic waste.

During the process acidic volatised gas is released into the air. Then you have solid waste such as scrap metal from the used base metals, slag and dust.

One of the main issues is the waste water. The original solution contains metals like zinc, nickel, and chromium. Galavanisation waste water often contains cyanide. All the type of stuff you don’t want in your drinking water.

Heavy metal contamination has multiple carcinogenic and non-carcinogenic risks. Though most people in China drink bottles water, the metals can still make it into your body through contact with the skin when showering and other activities. Children are particularly susceptible due to their skin’s increased ability to absorb the heavy metals.

Traditionally Chinese factories would drain the waste water into the sewage and water systems, solid waste would often go into land fills and gas would just disperse into the atmosphere.

China’s Response

Like many developed economies that got their start in manufacturing, China ignored environmental harm to allow for economic growth and like many other countries, once it was economically established it paid more attention to the environment and it’s workers.

The “2015 No. 64” document of the Ministry of Industry and Information Technology introduced a 5 year plan to control heavy metal pollution but also to stop low efficiency production and truly modernise the electroplating industry.

This involved moving factories away from population centres, consolidating electroplating zones along with treatment facilities. Preventing new construction and closing existing factories near natural and ecological reserves. Strict adherence to “Electroplating Pollutant Discharge Standard” (GB21900), “Integrated Wastewater Discharge Standard” (GB8978) and “Noise Standard for the Boundary of Industrial Enterprises” (GB12348) are now strict standards amongst electroplating facilities.

If they didn’t meet the new standards, a factory was forced to close.

Why This is Bad For Buyers

If you own a factory and you can pump out these cheap electroplated products then the government come in and says ‘you can’t dump your waste the way you have been doing for the past 15 years, you have to treat it like this which is more expensive’, because you’re a little factory with 50 staff, you have two options. Shut down permanently or open up a mega factory.

So your product manufacturer that was sending what they have produced to the electroplating factory, but now the factory they use is either closed down or it has moved 200 miles away, so your supplier either says they can’t do it anymore or the price has increased.

The main price increase of around 25 – 40% is due to membrane treatment of waste water. This price increase is of course only on the electroplating not the rest of an individual product.

What the Future Looks Like

One of the benefits of China’s political system is you can’t drag your feet. In the UK we have been talking about high speed rails for so long and nothing has happened. In China, they wanted a high speed rail so they built a high speed rail.

China has and continue to develop electroplating concentration areas with emission standards and disposal measures of various pollutants (exhaust gas, wastewater, solid waste, and noise at the boundary of the plant). At present there are more than 100 electroplating parks or clusters operational or under construction.

Small operators are prevented to open with rules such as

The total amount of bath liquid in the electroplating production process, including the cleaning tank, is not less than 30,000 liters.

The annual output value of electroplating production is more than 20 million yuan.

The output value of unit operation area is not less than 15,000 yuan/square meter.

Electroplating companies with a single variety and continuous production require more than 70% of automatic production lines and semi-automatic production lines.

Centralisation of plating factories and waste management facilities along with improved production efficiency, automation, reduction in transportation costs of raw material and buying power of larger output factories will see prices settling down in the future, keeping Chinese electroplating prices the best in the world.

Conclusion

Electroplating is the process of coating one metal with another for improved function and aesthetics. Pollution from the process, especially from waste water makes its way into drinking water and farmland. China’s response was to enact a 5 year plan in 2015 closing down smaller less efficient factories and moving factories to special zones equipped for large scale, automated and efficient manufacturing next to treatment facilities for waste disposal. Initial upheaval caused an increase in pricing and disruption to existing supply chains. The future of electroplating in China is one of increased efficiency, automation, controlled pricing and zero pollution.

If you have any questions about electroplating, manufacturing processes or our sourcing and freight services, please do not hesitate to get in touch using our contact form below.